Two important factors must be considered when selecting the type of gas gun.

The reflected liquid level pressure wave is larger when the volume or pressure of gas discharged into the casing annulus is increased. On deep, slim hole, low pressure wells, the liquid level response may be weak unless a large initial pressure pulse is used.

The compact gas gun consists of a 10 cubic inch volume chamber and quick opening gas valve. The chamber is usually filled with carbon dioxide or nitrogen gas to a pressure in excess of the well pressure. When the valve is opened, a pressure pulse is generated which travels through the wellbore gas. The chamber can be charged as needed to obtain the desired record.

If the well pressure is sufficient gas can be released from the well into the volume chamber to create a pressure pulse (implosion mode). An external gas source is not needed in this situation. Operating the Compact Gas Gun in the implosion mode allows debris from the well to be discharged into the gas gun volume chamber, resulting in greater maintenance requirements and the occasional replacement of o-rings.

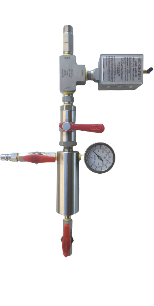

The Remote Fire Gas Gun utilizes a high performance microphone with an excellent signal-to-noise ratio along with a 12 cubic inch volume chamber.

A solenoid valve releases gas from the gas gun volume chamber into the well. The solenoid is operated automatically from the Well Analyzer system or the Model M. The Remote Fire Gas Gun cannot be operated in the implosion mode.

The Remote Fire Gas Gun is required for automatic acquisition of pressure transient data. It is normally supplied with a 1500 PSI pressure gauge and a 1500 PSI pressure transducer. The Remote Fire Gas Gun is limited to 1500 PSI working pressure.

Note: For single shot analysis, the 5000 PSI implosion gun is preferred when the well pressure exceeds 1500 PSI.

The Wireless Remote Gas Gun utilizes a high-performance microphone with an excellent signal-to-noise ratio along with a 12 cubic inch volume chamber.

A solenoid valve releases gas from the gas gun volume chamber into the well. The solenoid is operated automatically from the wireless system. The Wireless Remote Fire Gas Gun cannot be operated in the implosion mode.

The 5000 PSI Gas Gun is a manually operated gas gun excellent for use in gas lift, flowing, and high pressure shut-in wells. While it is most commonly used in implosion mode, it can also be operated in explosion mode.

The 5000 PSI Gas Gun can be operated in implosion mode on wells with a casing pressure greater than 200 PSI. The 1/2″ ball valve is rapidly opened to release gas from the well into the volume chamber. This action generates a rarefaction (negative) pressure pulse. A compressed gas source is not needed in the implosion mode.

Use the explosion mode on low-pressure wells (less than 200 PSI), and where pressurized gas is available at a pressure greater than the casing annulus pressure. In the explosion mode, the gas gun volume chamber is pressured above the casing pressure. Opening the gas valve results in a positive compression pressure wave being generated which travels down the casing annulus gas.

When the 5000 PSI Gas Gun becomes dirty due to debris, the volume chamber and microphone assembly may be flushed with a solvent to remove the debris.

The Wireless 5000 PSI Gas Gun can be operated in implosion mode on wells with a casing pressure greater than 200 PSI. The 1/2″ ball valve is rapidly opened to release gas from the well into the volume chamber. This action generates a rarefaction (negative) pressure pulse. A compressed gas source is not needed in the implosion mode.

Use the explosion mode on low-pressure wells (less than 200 PSI), and where pressurized gas is available at a pressure greater than the casing annulus pressure. In the explosion mode, the gas gun volume chamber is pressured above the casing pressure. Opening the gas valve results in a positive compression pressure wave being generated which travels down the casing annulus gas.

When the Wireless 5000 PSI Gas Gun becomes dirty due to debris, the volume chamber and microphone assembly may be flushed with a solvent to remove the debris. Please refer to the W5KG Operating Manual for further instruction on maintenance and operation.

In implosion mode, the volume chamber in the gas gun is bled to a pressure less than the well pressure, after which a poppet valve is rapidly opened to release gas from the well into the gas gun volume chamber in order to generate the pressure pulse.

The microphone is not noise-canceling and is less sensitive than the microphones on the Compact Gas Gun, Remote Fire Gas Gun or the 5000 PSI Gas Gun.

The 15,000 PSI Gas Gun performs best at pressures between 1,500 and 15,000 PSI. However, good results have been obtained at pressures above 1500 PSI (100 ATM) through the use of the 1/8″ orifice needle valves which are standard on most high pressure wells.